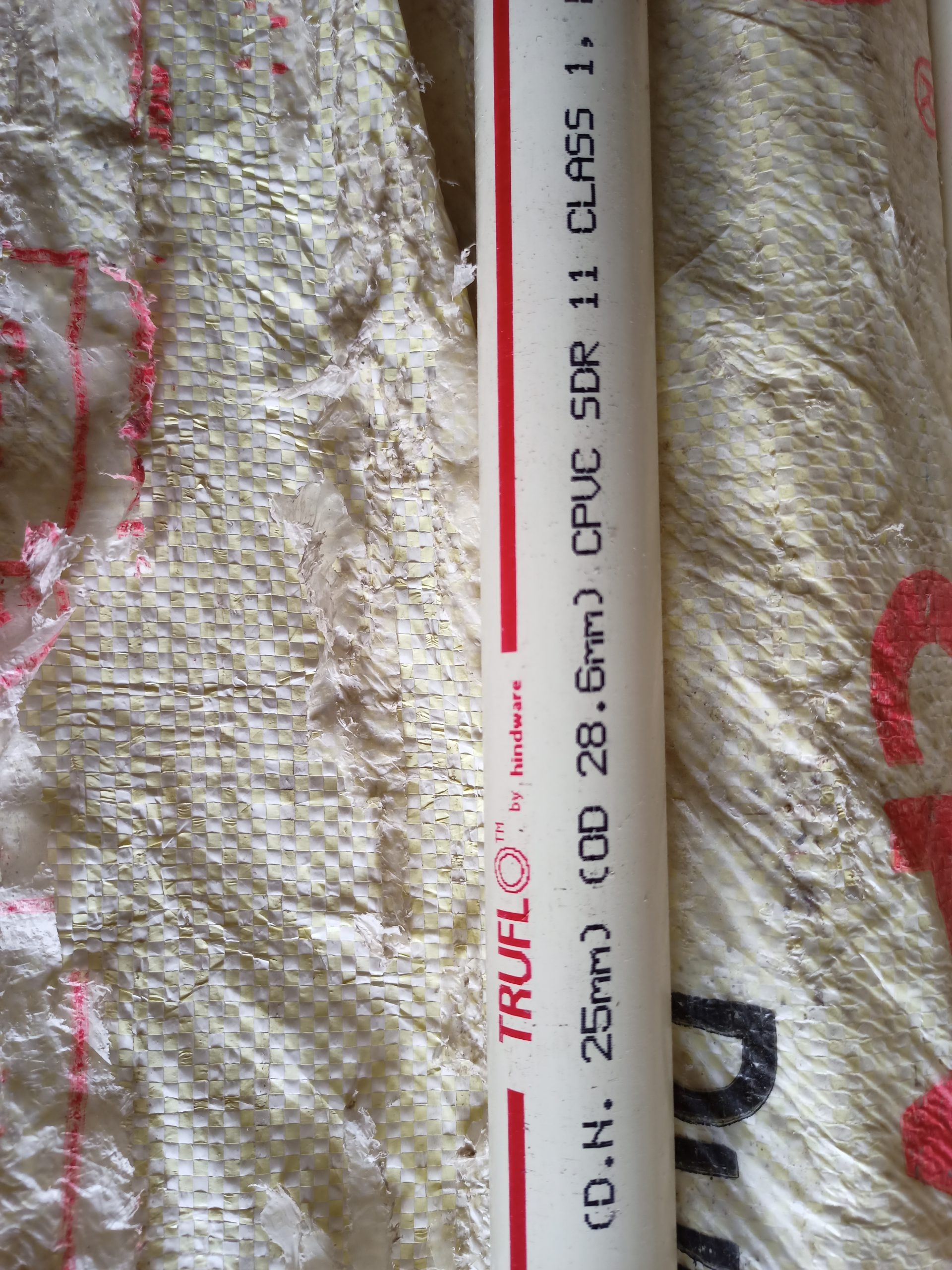

Brand: Truflo by Hindware

Length: 3 Meter/ 10 Ft

Type: CPVC

Warranty: Avail the warranty benefits by using Truflo pipes with Truflo fittings & solvent cement

Assembly: Any local plumber can fix it easily

Material: Durastream CPVC compound

Pack Content: 1 Pipe

HIGHLIGHT OF THE PRODUCTS

- Ideal for hot and cold water applications

- Suitable for water temperature upto 93oC

- Wide range of pipes and fittings from 1⁄2″ to 6″ (15 mm to 150 mm)

- Pipes & Fittings upto 2″(50 mm) can withstand 28.1kg/cm2 pressure at 27oC and 6.93kg/cm2 at 82oC

- Safe for potable water

- UV Stabilised

- No bacterial growth

- Ease of installation

- Designed for over 50 years life

- Pipes upto 2″ (50 mm) are manufactured as per IS:15778:2007 and fittings as per ASTM 2846 standards

- Pipes above 2″ (50 mm) are manufactured as per ASTMF 441 & Fittings as per ASTMF 438 & 439

PRODUCT AVAILABILITY, PRESSURE RATING AND STANDARDS

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM3 | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 27OC | 82OC | ||

| SDR 11 | 1⁄2” to 2” (15 mm to 50 mm) |

IS:15778:2007 | ASTM D 2846 | 28.1 | 6.93 |

| SDR 13.5 | 1⁄2” to 2” (15 mm to 50 mm) |

IS:15778:2007 | – | 22.23 | 5.61 |

| GRADE | DIAMETER | STANDARD | OPERATING PRESSURE KG/CM3 | ||

|---|---|---|---|---|---|

| PIPES | FITTINGS | 23OC | 82OC | ||

| SCH 40 | 2 1⁄2” (65 mm) | ASTM F 441 | ASTM F 438 | 21.09 | 5.27 |

| SCH 40 | 3” (80 mm) | ASTM F 441 | ASTM F 438 | 18.28 | 4.57 |

| SCH 40 | 4” (100 mm) | ASTM F 441 | ASTM F 438 | 15.47 | 3.87 |

| SCH 40 | 6” (150 mm) | ASTM F 441 | ASTM F 438 | 12.66 | 3.16 |

| SCH 80 | 2 1⁄2” (65 mm) | ASTM F 441 | ASTM F 439 | 29.53 | 7.38 |

| SCH 80 | 3” (80 mm) | ASTM F 441 | ASTM F 439 | 26.01 | 6.33 |

| SCH 80 | 4” (100 mm) | ASTM F 441 | ASTM F 439 | 22.49 | 5.62 |

| SCH 80 | 6” (150 mm) | ASTM F 441 | ASTM F 439 | 19.69 | 4.92 |

CPVC IS RESISTANT TO WATER TEMPERATURE

a. 93°C for SHORT term application

b. 82°C for CONTINUOUS application. It keeps hot water hotter and cold water colder as compared to GI and copper plumbing

| TEMPERATURE DE-RATING FACTOR FOR CPVC | |

|---|---|

| WORKING TEMPERATURE | DE-RATING FACTOR |

| OC | |

| 23-27 | 1.00 |

| 32 | 0.91 |

| 38 | 0.82 |

| 49 | 0.65 |

| 60 | 0.50 |

| 71 | 0.44 |

| 82 | 0.25 |

| 93 | 0.20 |

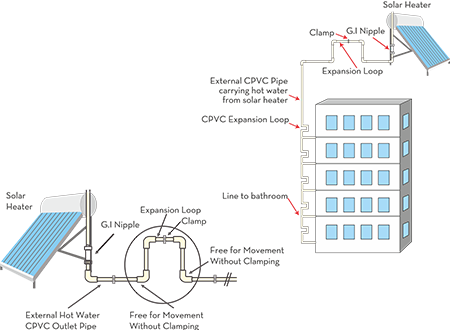

INSTALLATION PROCEDURE

A. Guidelines

- Connect minimum 1 mtr. Length of metal pipe to the outlet of hot water tank.

- Ventilation-proper air-venting on the hot water outlet side is a must.

- Use of expansion loop is highly recommended to avoid snaking effect caused due to expansion & contraction of pipe.

- Although CPVC has the lowest thermal conductivity amongst all alternate plastic plumbing systems, however to maintain thermal efficiency, it is recommended that the pipes should be insulated. PE foam may be used over the pipe to provide adequate insulation.

B. Horizontal and vertical spacing for pipe supporting(clamping of pipes)

| NOMINAL PIPE DIA | SPACING | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| INCH | MM | 20°C | 50°C | 70°C | 80°C | ||||

| FT | MTR | FT | MTR | FT | MTR | FT | MTR | ||

| 1⁄2” (15 mm) | 12.00 | 5.50 | 1.70 | 4.50 | 1.40 | 3.00 | 0.90 | 2.50 | 0.80 |

| 3⁄4” (20 mm) | 19.00 | 5.50 | 1.70 | 5.00 | 1.50 | 3.00 | 0.90 | 2.50 | 0.80 |

| 1″ (25 mm) | 25.00 | 6.00 | 1.80 | 5.50 | 1.70 | 3.50 | 1.10 | 3.00 | 0.90 |

| 1 1⁄4” (32 mm) | 32.00 | 6.50 | 2.00 | 6.00 | 1.80 | 3.50 | 1.10 | 3.00 | 0.90 |

| 1 1⁄2” (40 mm) | 40.00 | 7.00 | 2.10 | 6.00 | 2.00 | 3.50 | 1.10 | 3.50 | 1.10 |

| 2″ (50 mm) | 50.00 | 7.00 | 2.10 | 6.50 | 2.00 | 4.00 | 1.20 | 3.50 | 1.10 |

| 2 1⁄2” (65 mm) | 65.00 | 8.00 | 2.40 | 7.50 | 2.30 | 4.50 | 1.40 | 4.00 | 1.20 |

| 3″ (80 mm) | 80.00 | 8.00 | 2.40 | 7.50 | 2.30 | 4.50 | 1.40 | 4.00 | 1.20 |

| 4″ (100 mm) | 100.00 | 9.00 | 2.70 | 8.50 | 2.60 | 4.50 | 1.40 | 4.50 | 1.40 |

| 6″ (150 mm) | 150.00 | 10.00 | 3.00 | 9.00 | 2.70 | 5.50 | 1.70 | 5.50 | 1.50 |

Do not clamp supports tightly, it restricts the movement of pipe caused because of expansion and contraction.

INSTALLATION WITH SOLVENT CEMENT

SOLVENT CEMENTED JOINTING

a. Dry fitment-check joint of pipe to fitting without solvent cement, should fit up to 60 – 70%

b. Cold fusion joint (cold welded joint)

c. For diameters 1⁄2” to 2”, single step solvent cement

d. For diameters 21⁄2” to 4”, 2 step solvent cement (primer + solvent cement)

e. Primer helps to clean the surface of pipe & fitting and softens the material

| AVERAGE INITIAL SET SCHEDULE FOR CPVC SOLVENT CEMENT | |||

|---|---|---|---|

| TEMP RANGE | PIPE SIZE 1⁄2” – 11⁄4” | PIPE SIZE 11⁄2” – 3” | PIPE SIZE 31⁄2” – 4” |

| 16° – 38°C | 2 minutes | 5 minutes | 30 minutes |

| 5° – 16°C | 5 minutes | 10 minutes | 2 hours |

| -18° – -5°C | 10 minutes | 15 minutes | 12 hours |

Note – Typical set schedule is required time before it is advisable to carefully handle joint. In wet or humid conditions, additional set time maybe required of up to 50% of amount listed. Use as general guidelines only.

f. Cure time-Curing time is longer than the set time. Curing means the joint has completely matured

g. The pressure test can only be performed after the joint is completely cured

| AVERAGE JOINT CURE SCHEDULE FOR CPVC SOLVENT CEMENT | ||||||

|---|---|---|---|---|---|---|

| RELATIVE HUMIDITY60% OR LESS | PIPE ∅ 1⁄2” – 11⁄4” | PIPE ∅ 11⁄2” – 2” | PIPE ∅ 21⁄2” – 4” | |||

| TEMP. RANGES DURING ASSEMBLY & CURE PERIODS | BAR | BAR | BAR | |||

| UP TO 11 | 11 TO 26 | UP TO 11 | 11 TO 22 | UP TO 11 | 11 TO 22 | |

| 16° – 38°C | 15 min | 6 hrs | 30 min | 12 hrs | 1 1⁄2 hrs | 24 hrs |

| 5° – 16°C | 10 min | 12 hrs | 45 min | 24 hrs | 4 hrs | 48 hrs |

| -18° – -5°C | 15 min | 48 hrs | 1 hr | 96 hrs | 72 hrs | 8 days |

Note – Joint cure schedule is the necessary time to allow before pressurizing system. In damp or humid weather allow 50% more cure time.

In case of using paint on CPVC piping system, use only Latex based paints which are water based to make it workable and brushable. No Oil/Solvent based paints are to be used as these paints can drastically reduce the life of the systems.

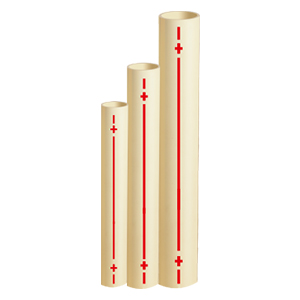

| TYPE OF PIPE | COLOUR | IMAGE |

|---|---|---|

| SDR 11 | Red strip |  |

| SDR 13.5 | Brown strip | |

| SCH 40 | Brown strip | |

| SCH 80 | Red strip |

CPVC PLUMBING SYSTEM FOR HOT & COLD WATER

CPVC PIPES – HSN CODE 3917

SDR 11/SDR 13.5 Pipes Manufactured as per IS15778:2007

There are no reviews yet.