Stainless steel filters are primarily made from high-quality stainless steel, a versatile alloy known for its corrosion resistance and durability. The main material used in stainless steel filters is stainless steel, which is composed primarily of iron, along with a minimum of 10.5% chromium. This chromium content forms a protective layer of chromium oxide on the surface of the steel, providing excellent resistance to rust, corrosion, and staining.

In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, and titanium. These alloying elements enhance the material’s mechanical properties and further improve its corrosion resistance in specific environments. For example, the addition of nickel increases the resistance to acids and enhances toughness, while molybdenum improves resistance to chloride corrosion and pitting.

Stainless steel filters can be manufactured using different types of stainless steel grades, depending on the specific filtration requirements and environmental conditions. Commonly used grades include 304 stainless steel (also known as 18-8 stainless steel), 316 stainless steel (with higher corrosion resistance), and duplex stainless steels (combining the benefits of austenitic and ferritic stainless steels).

The choice of stainless steel grade depends on factors such as the filtration application, operating temperature, chemical exposure, and desired filtration efficiency. By selecting the appropriate stainless steel grade, manufacturers can ensure that the filter offers optimal performance, longevity, and resistance to the intended operating conditions.

features of stainless filter :

Stainless steel filters offer a range of features that make them a popular choice for various filtration applications. Here are some key features of stainless steel filters:

Stainless steel filters are highly resistant to rust, corrosion, and staining due to the presence of chromium in the alloy. This makes them suitable for use in environments with exposure to liquids, gases, and chemicals.

Stainless steel filters are known for their high structural integrity and stability. They can withstand high temperatures, pressures, and harsh operating conditions without compromising their filtration performance, ensuring long-lasting durability.

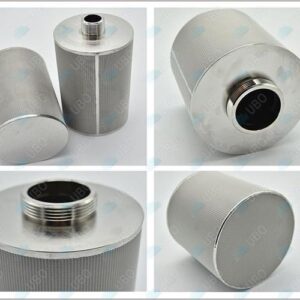

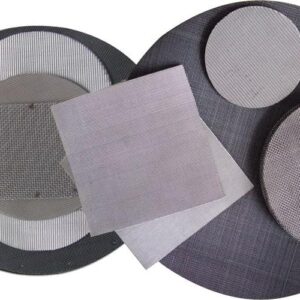

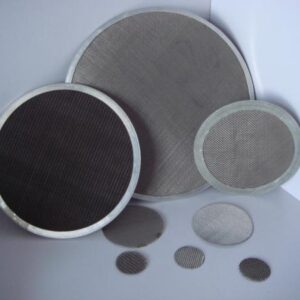

Stainless steel filters are available in various configurations, including woven wire mesh, perforated metal, and sintered metal. This allows for customization to meet specific filtration requirements, such as controlling the mesh size and aperture size.

There are no reviews yet.